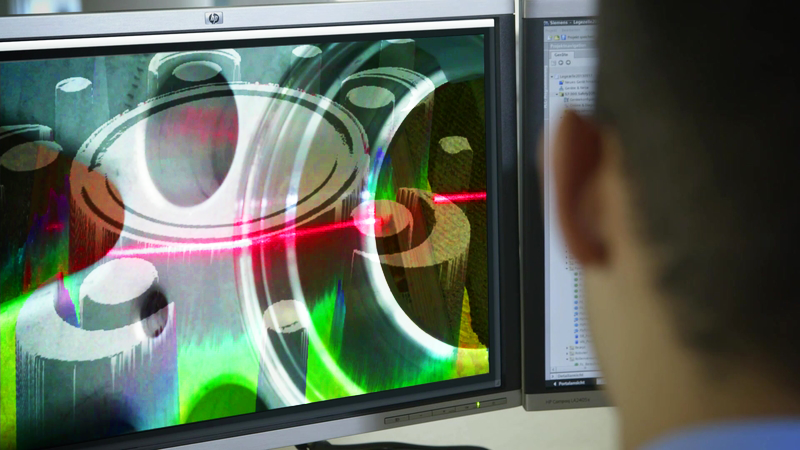

IMAGE PROCESSING GUARANTEES A CLEAR VIEW

Does your system have everything under control?

With a view for the essential’s quality improvement is reliable. 2D and 3D image processing enables your machine to take a closer look at key points in the process.,

This allows the next step to be taken with greater accuracy and the result to be perfected.